Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

1.The structure and working principle of split set Anchor Bolt

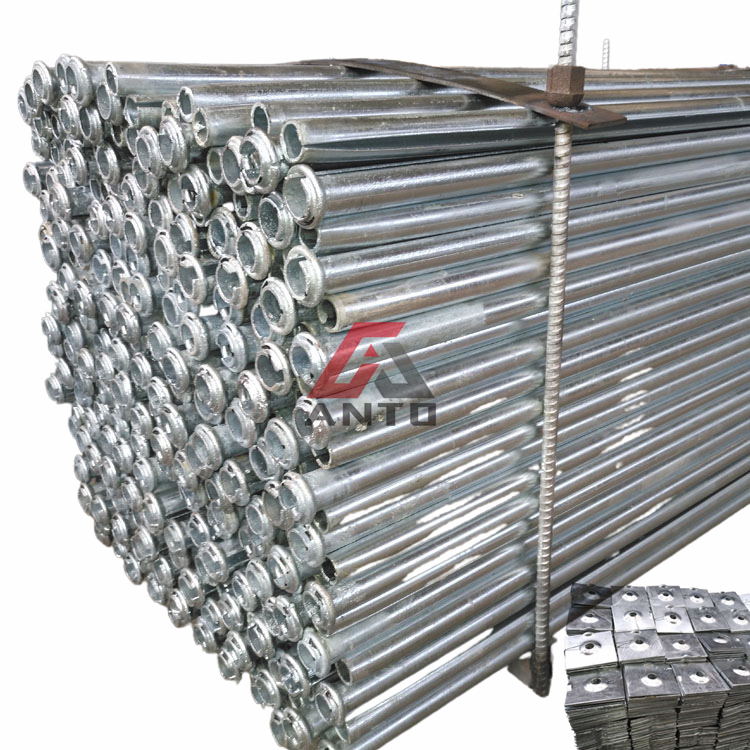

The mining Split Set Bolt is a kind of mine bolts(mining rock bolts),which is composed of a rod body and a tray, and has a simple structure. Its specifications: the rod body length is 1.7m, 44mm, the pipe wall thickness is 3mm, the pipe seam width is 10-15mm, the outer diameter tray is square, and the size is 130×130× 4.5mm. The pipe-slotted anchor is a full-length anchoring type. Its basic working principle is to use external force to drive the anchor into a borehole smaller than the outer diameter of the anchor, and use the elasticity of the steel pipe to generate radial pressure on the hole wall to make the anchor and The frictional resistance between the hole walls and the supporting force of the tray under the bolts make the surrounding rock of the roadway under three-way stress, so as to strengthen the surrounding rock and prevent its movement to stabilize it.

2. A few points of knowledge

(1) After the Split Set Rock Bolt is installed, it can immediately apply three-dimensional stress to the surrounding rock to actively reinforce the surrounding rock.

(2) The split set Rock Bolt is a full-length anchor rod, and its rod body is also elastic and flexible, so it can effectively resist the shearing force of the surrounding rock anywhere within the control range of the anchor rod, and the anchoring force is not destroyed.

(3) The split set anchor has simple structure, convenient installation and operation, and reliable working performance.

(4) The anchoring force of Split Set Friction Bolt is greatly affected by the difference between the pipe diameter and the borehole diameter. If the difference is small, the installation will be difficult, and if the difference is large, the anchoring force will be small.

(5) After the bolt is installed, with the increase of time, under the conditions of blasting vibration and rock mass displacement, the anchoring force is not attenuated but increased significantly. The reasons are as follows: First, the joint-type bolt is subjected to the full-length force. , It will not produce stress concentration like its anchor rod, and generally will not creep and relax to reduce the anchoring force. The second is the strain displacement or dislocation of the different rock layers around the bolt. The blasting shock and vibration will cause the bolt to deform locally in the axial direction, so that the rock mass compresses the bolt more tightly, and the anchoring force is obviously increased; In soft rock or swelling rock formations, as time goes by, the rock hole will gradually shrink, and the pipe diameter will continue to be compressed, so that the bolt will generate greater tension, and the friction between it and the hole wall will increase correspondingly, so the anchoring force will be Increase with time. Fourth, because the split set rock bolt is full-length anchoring, the anchoring force still exists when the anchor is pulled or moved with the rock mass, and it will not fail like fast-hardening cement anchors.

ANTO Mining Bolts

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.