Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Cables

A comprehensive review of cable support in underground mining has been given in a book by Hutchinson and Diederichs (1996). This book is highly recommended for anyone who is concerned with the selection and installation of cable support for either mining or civil engineering applications.

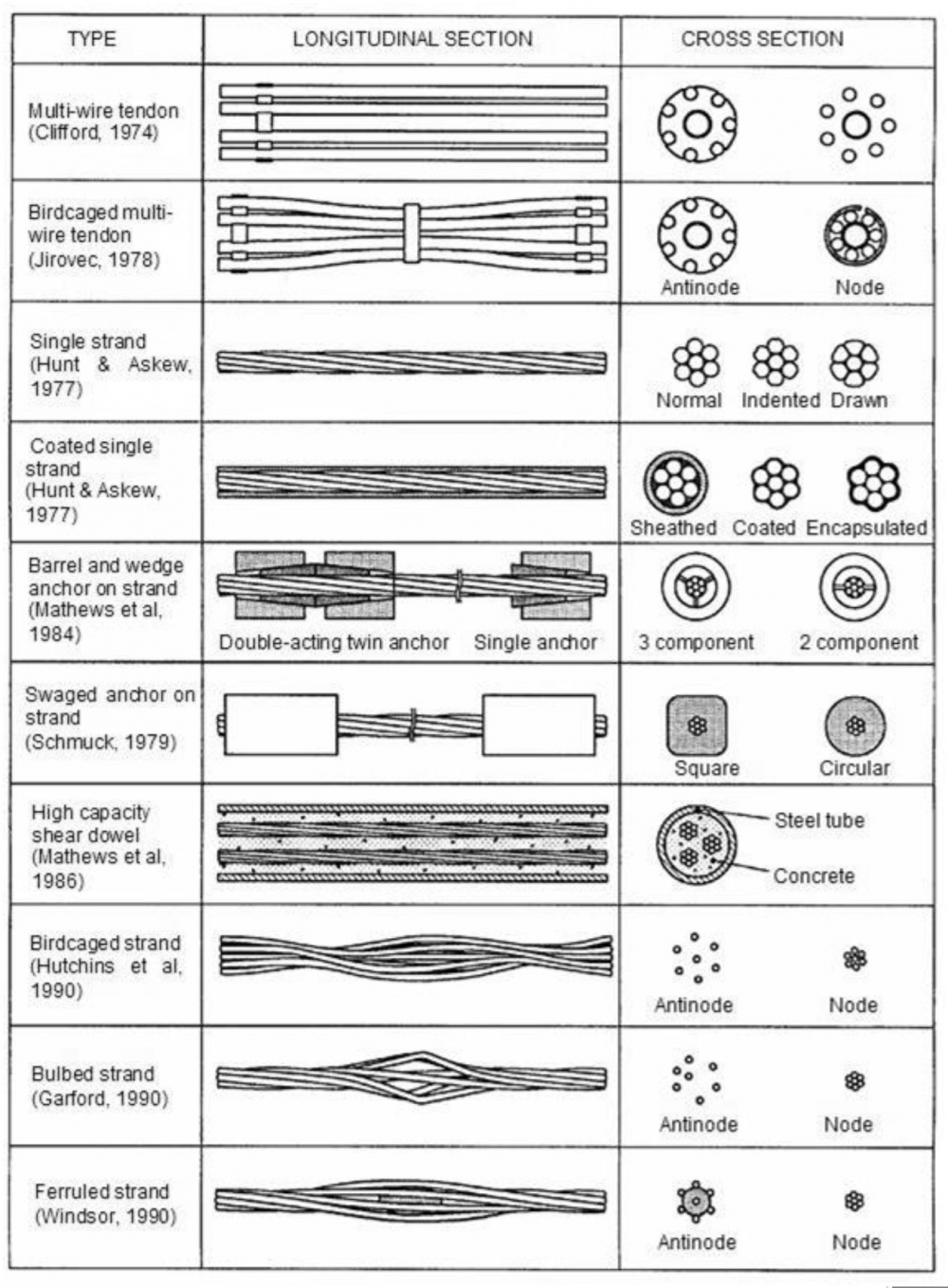

Some of the main cable types used by mining were summarised by Windsor (1992) and are illustrated in figure below.

Summary of the development of cable reinforcing systems for underground mining (Windsor, 1992).

Bond strength

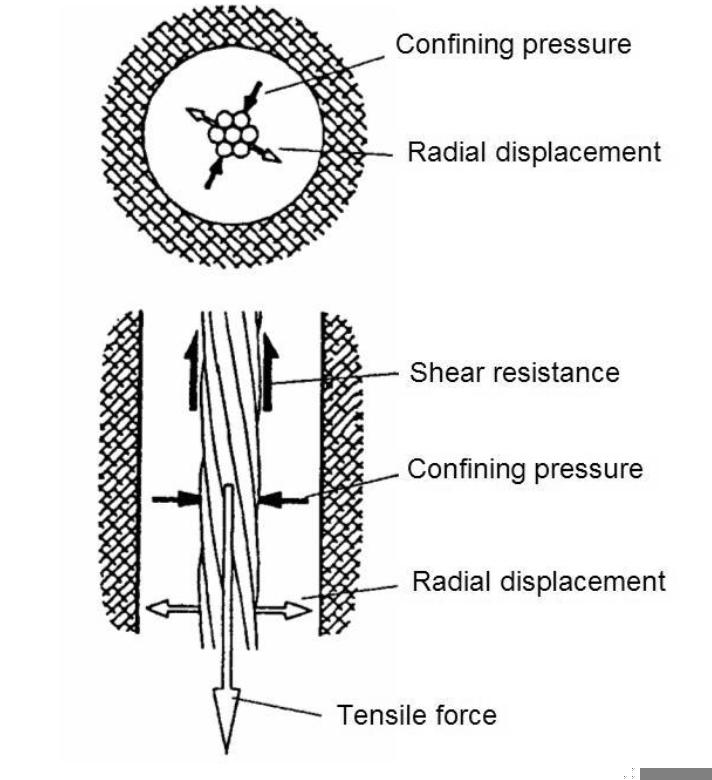

The forces and displacements associated with a stressed cable grouted into a borehole in rock are illustrated in figure below.

Forces and displacements associated with a stressed cable grouted into a borehole in rock.

As the cable pulls out of the grout, the resultant interference of the spiral steel wires with their associated grout imprints or flutes causes radial displacement or dilation of the interface between the grout and the cable. The radial dilation induces a confining pressure that is proportional to the combined stiffness of the grout and the rock surrounding the borehole. The shear stress, which resists sliding of the cable, is a product of the confining pressure and the coefficient of friction between the steel wires and the grout. Shear strength, therefore, increases with higher grout strength, increases in the grout and the rock stiffness and increases in the confining stresses in the rock after installation of the cable. Conversely, decrease in shear strength can be expected if any of these factors decrease or if the grout crushes.

Theoretical models of the behaviour of this rock/grout/cable system have been developed by Yazici and Kaiser (1992), Kaiser et al (1992), Hyett et al (1992). The second of these models has been incorporated into the program PHASE2.

Grouts and grouting

The question of grout quality has always been a matter of concern in reinforcement systems for underground construction. One of the critical factors in this matter has been the evolution of grout pumps capable of pumping grouts with a low enough water/cement ratio (by weight) to achieve adequate strengths. Fortunately, this problem has now been overcome and there is a range of grout pumps on the market which will pump very viscous grouts and will operate reliably under typical underground

conditions.

The results of a comprehensive testing programme on Portland cement grouts have been summarised by Hyett et al (1992) and Figures 12, and 13 are based upon this summary. Figure 12 shows the decrease in both 28 day uniaxial compressive strength and deformation modulus with increasing water/cement ratio. Figure 13 gives Mohr failure envelopes for three water/cement ratios. These results show that the properties of grouts with water/cement ratios of 0.35 to 0.4 are significantly better than those with ratios in excess of 0.5. However, Hyett et al found that the scatter in test results increased markedly for water/cement ratios less than 0.35. The implication is that the ideal water/cement ratio for use with cable reinforcement lies in the range of 0.35 to 0.4.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.