Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

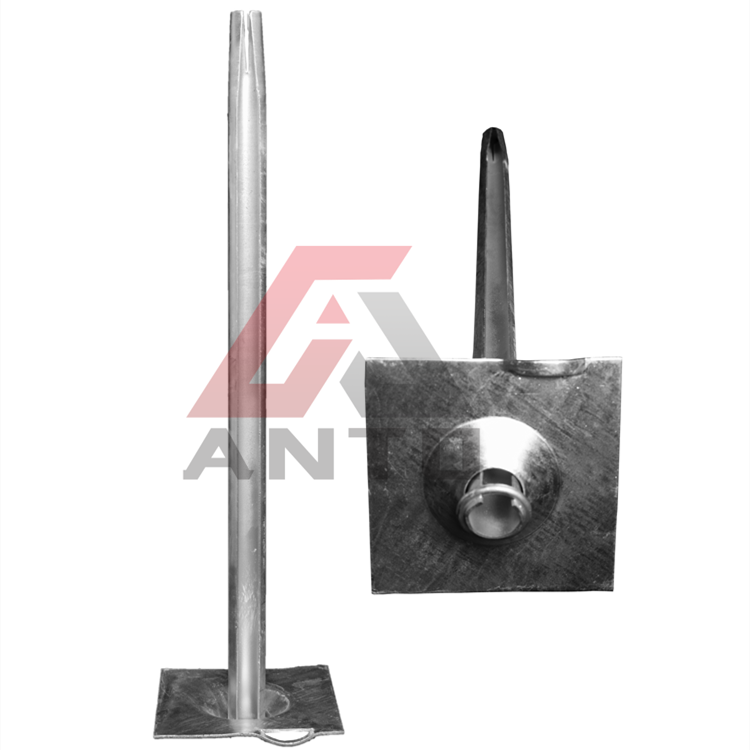

Mining Friction Bolts

Features

●The Friction Bolt is manufactured from high strength steel tube which has a slot along its entire length. A ring, or collar, is welded on the outer end to hold a domed plate to the rock surface.

●The 33mm and 39mm Friction Bolt is suitable for installation with hand held rock drills (stoppers or drifters). The 46mm Friction Bolt is NOT suitable for installation with hand held rock drills.

●Friction bolts can be load tested by fitting a special ring to the bolt prior to its installation. Pull tests can then be conducted with a hollow ram hydraulic jack.

●Further corrosion protection can be provided by hot dip galvanising.

Installation Guidelines

●The hole length should be longer than the bolt,nominally 150mm, to allow for any rock fretting during installation.

●The friction bolt is inserted into the hole. The driving dolly is fitted into the rock drill`s chuck and then the bolt (with accessories) is placed onto the dolly.

●Using full percussion and thrust the bolt is fully driven into the hole until the domed plate is firmly against the rock surface. Care should be taken to ensure the rock drill`s feed/thrust is in the same orientation as the hole or the bolt may be bent during installation.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.