Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Abstract: As a more effective support method in roadway construction, Mining Friction Bolt support has been widely used and promoted in our mine tunnel driving process. However, there are still some problems in the actual operation of Pipe Joint Bolt support in our mine. Taking corresponding measures will have important guiding significance for the construction of mining Friction Bolt support in the future.

Keywords: mining friction bolt; mining support; problem; countermeasure

Preface

With the promotion and use of mining friction bolt support in our mine, according to the application in different rock formations and geological structures, various data are collected under different conditions for comparison and analysis. However, it is still limited by the scope of use and experience. Through the analysis of the geological structure exposed by the construction roadway, the use of reasonable support parameters, and the reasonable safety construction organization, the use of mining friction bolt support not only improves the roadway support effect, but also realizes the safe and rapid excavation of the roadway. However, there are still some problems in the construction process. Taking corresponding countermeasures will have important guiding significance for the construction of mining friction bolt support in the future.

1 Overview

Wuci Coal Mine is a subordinate mine of Fumei (Zhangping) Coal Industry Co., Ltd. The main coal seams of this mine are 38#, 38#1, 39# coal seams in the first section of Tongziyan Formation. The working face is located at +570-39# Dongyun Lane in the second mining area of Wuci Coal Mine, which is mainly responsible for the centralized discharge of gangue (coal), pedestrians, material transportation, ventilation, etc.; the roadway is located at 39# coal seam floor, The lithology of the construction roadway is mainly: fine siltstone, sandy mudstone, etc., with a lithological hardness coefficient f=4~6, mainly monoclinic structure. During the construction process, the surrounding rock bedding is relatively developed and easy to delamination. According to the construction exposure and the analysis of geological structure, mining friction bolt are used for support; in principle, the anchor holes are arranged according to the "triple eye" type, and anchors are used. The row and spacing of the rods are 1.0m×1.0m.

2 Application of mining friction bolt support technology

2.1 Working principle and characteristics of mining friction bolt support

2.1.1 The working principle of mining friction bolt support

Install the mining friction bolt in a borehole smaller than the pipe diameter. At this time, three forces will be applied to the surrounding rock. One is the radial pressure on the hole wall within the full length of the slotted anchor. One is the friction force to prevent the surrounding rock from sliding down, and the other is the supporting force of the friction bolt domed plate; these three forces make the surrounding rock more stable, thereby supporting the surrounding rock. Bolt support mainly plays the role of suspension, composite beam, and squeezing reinforcement; it improves the integrity and stability of the surrounding rock of the roadway from the surface.

2.1.2 Features of mining friction bolt support

(1) Support is in place in time. The mining friction bolt support can be very timely, and it can follow the most head-on support method of the driving roadway, which can effectively avoid the production of empty roof work on the working face. As long as the mining friction bolt support is pushed in the bolt eye, the anchoring force produced by it can be achieved, the supporting effect is better, and it can reduce the roof fall of the working face or other unsafe hidden dangers caused by the untimely supporting.

(2) The installation process is simple. Compared with the previous similar bolt support process, the mining friction bolt support has the advantages of simple technology, high degree of mechanization, easy operation, and better support quality.

(3) Effective cost saving. Compared with metal shed support or masonry support, mining friction bolt support not only actively supports the rock, but also reduces the slab accident caused by the deformation of the roadway, extends the support period, and realizes energy saving and consumption reduction. Purpose, in the long run, the support cost has been significantly reduced; and the probability of weathering and shedding of roadway rocks is greatly reduced, the amount of roadway maintenance is small, and the single entry level of the roadway is also improved.

(4) Advantages of mining friction bolt in advance support. The soft coal seam and broken rock layer can be anchored to form an arch beam structure, which increases the overall strength of the coal seam and rock layer, and turns the coal rock mass that is not easy to control into a coal rock mass with a relatively stable time, creating effective support for construction Under certain conditions, the construction is carried out safely and smoothly.

2.2 Relevant parameters and selection of mining friction bolt

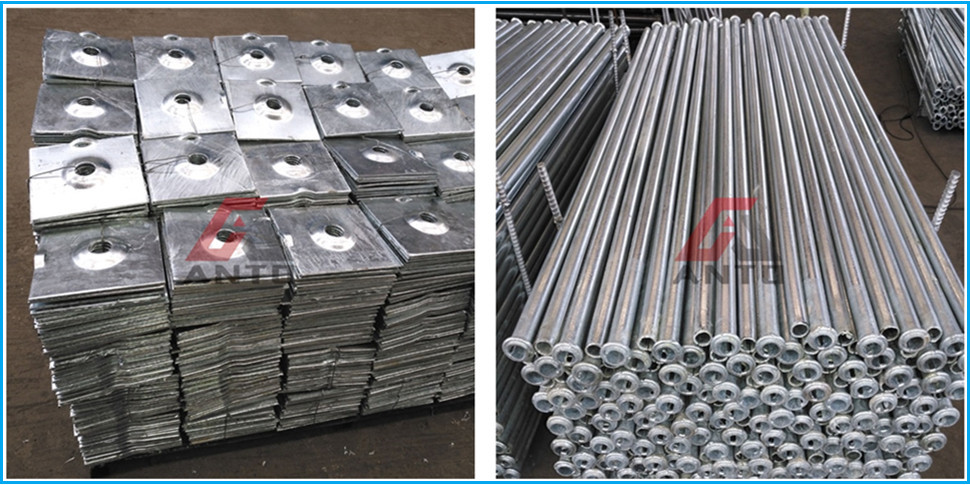

2.2.1 The friction bolt is a new type of anchor rod that is fully anchored and actively strengthens the surrounding rock. Its three-dimensional part is a high-strength steel pipe with longitudinal slits. When installed in a borehole slightly smaller than the pipe diameter It can immediately exert pressure on the hole wall over the full length and prevent the sliding of the surrounding rock from sliding, plus the supporting force of the anchor rod tray, so that the surrounding rock is in a three-way stress state, and the rock formation is stabilized.

2.2.2 Main technical requirements: The surface of the pipe anchor rod should be flat without serious strain or corrosion. The weld should be free of cracks, no pores and slag, and it is not allowed to burn through the pipe wall. The domed plate should be able to move freely on the rod. It is advisable for the retaining ring interface and the pipe seam opening to be misaligned by 170°-190°; the retaining ring weld pull-off force is ≥80KN, the ultimate tensile strength of the rod body is ≥110kN, the initial anchoring force is ≥25KN/m, and the plate bearing capacity is ≥65KN.

2.2.3 Technical performance: Initial anchoring force: 3~7 tons; pipe ring pull-off load: 8~10 tons; anchor pipe tensile breaking capacity: 12~13 tons; corrosion resistance is 20~30% higher than A3 steel , Conducive to long-term use.

2.2.4 Selection of supporting materials. Our mine chooses the Ф34×1600 pipe seam anchor (including tray) produced, Ltd. The pipe wall thickness is 2.0mm, the pipe length is 1600mm, the outer pipe diameter is 34mm, and the slit is 12mm. Use YT-24 pneumatic drill with Ф32mm long and short drill rod long holes.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.